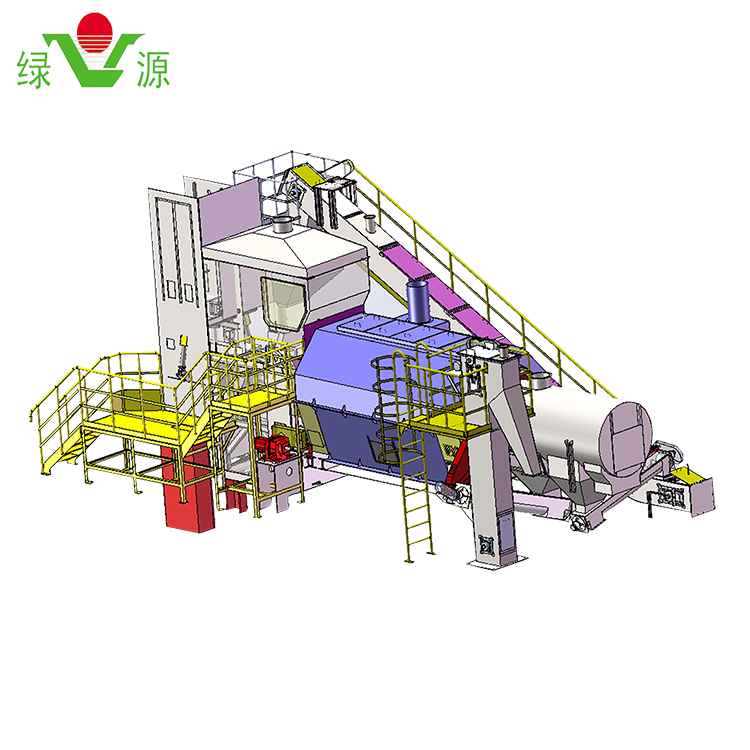

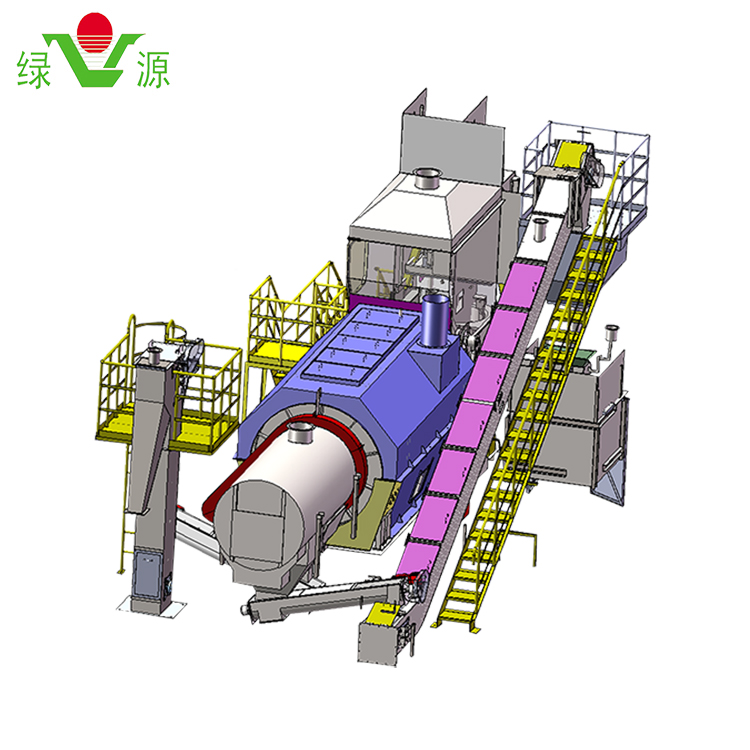

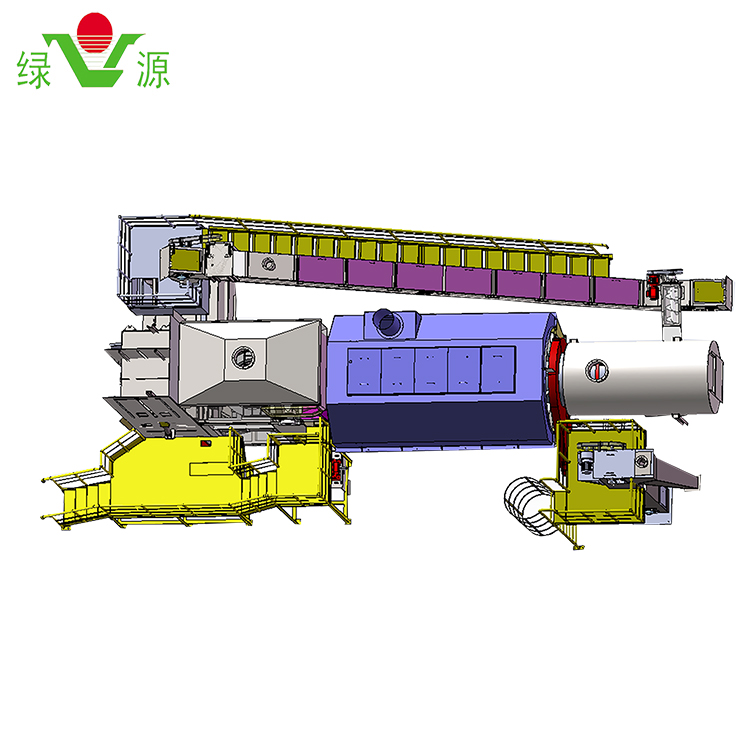

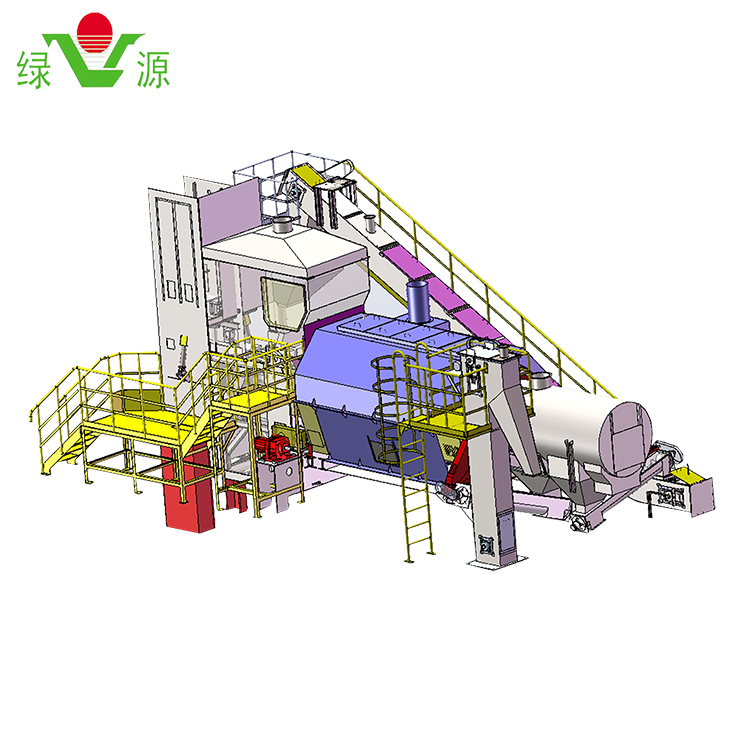

Automatic new type ash frying machine Aluminum ash separation equipment

Automatic new type ash frying machine Aluminum ash separation equipment

Advantages of Automatic Aluminum Slag Processing Equipment

Advantages of Automatic Aluminum Slag Processing Equipment

1.The area is small and the form of the foundation is relatively simple, which reduces the additional expenditure of some foundations.

2. The environmental protection performance is better: because the mobile aluminum slag pot is used to connect the aluminum slag to the furnace mouth and directly put into the ash-frying equipment, the aluminum slag separation operation is performed. Reduced the step of pouring hot aluminum slag directly into the fixed aluminum slag pot, and also avoided a large amount of soot generated by tipping (some of the soot is caused by the combustion of liquid aluminum and oxygen contact and combustion).

3. High Degree of Automation: After the separation of aluminum and water, the method of automatic tipping is used to introduce the hot residue into the cooling barrel through the chute (reducing the requirements for the difference in foundation height); The medium-grain aluminum residue after screening passes through the spiral conveyors, scraper and put the machine together with the ash job is automatically added to the next pot in the particles used, the benefits of (recycled particles: A. can reduce the temperature of a high temperature aluminum dross in order to achieve the most Better frying ash temperature; B. Re-extract the available aluminum in the middle ash to increase the recovery rate; C. Reduce the probability of crusting).

4. It is more convenient to replace the wearing parts: the pot, mixing blade and top in the ash frying operation can be flexibly transported out/disassembled.

5. The operation process of the whole set of aluminum slag processing equipment is controlled by PLC program. The operator can complete the control of the equipment only through the touch screen/remote control, which greatly improves the work efficiency.

自动铝渣处理设备的优势

1,占地面积小,地基形式相对简单,减少了一些地基的额外支出。

2.环保性能更好:由于使用移动式铝渣罐将铝渣连接到炉口并直接放入灰炉中,因此可以进行铝渣分离操作。减少了将热铝渣直接倒入固定铝渣罐中的步骤,还避免了由于倾翻而产生的大量烟灰(一些烟灰是由液态铝的燃烧和氧气接触以及燃烧引起的)。

3,自动化程度高:铝,水分离后,采用自动倾卸的方法,将热残渣通过溜槽引入冷却桶中(减少了对地基高度差的要求);筛分后的中粒铝残留物通过螺旋输送机,刮板并与灰分一起放入机器中,然后自动将所使用的颗粒添加到下一个锅中,好处是(回收颗粒:A。可以降低高温铝渣,以达到最佳的炸灰温度; B。重新提取中间灰中的可用铝以提高回收率; C。降低结皮的可能性)。

4.更换易损件更方便:灰炸操作中的锅,搅拌叶片和炉头可灵活运出/拆卸。

5,整套铝渣处理设备的运行过程由PLC程序控制。操作人员仅通过触摸屏/遥控器即可完成设备的控制,大大提高了工作效率。