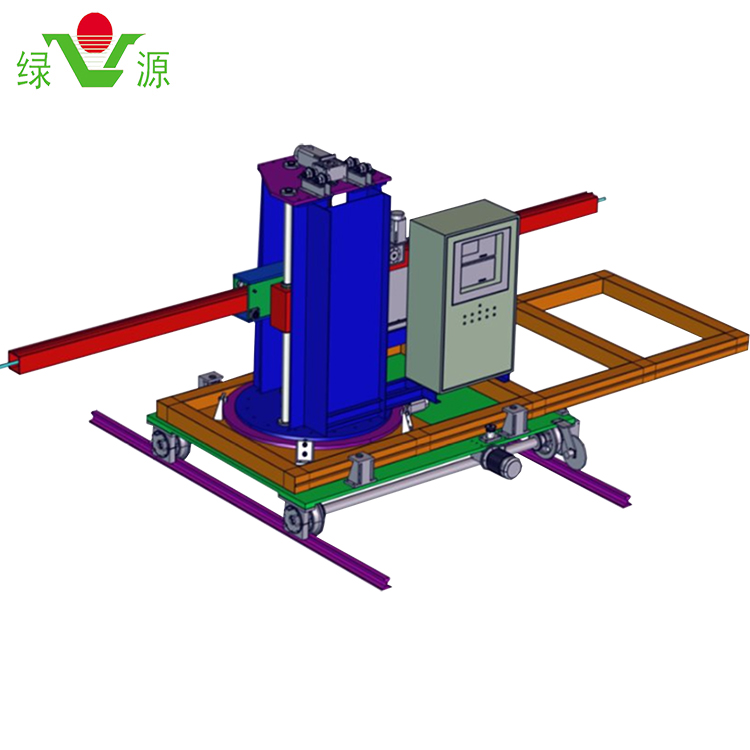

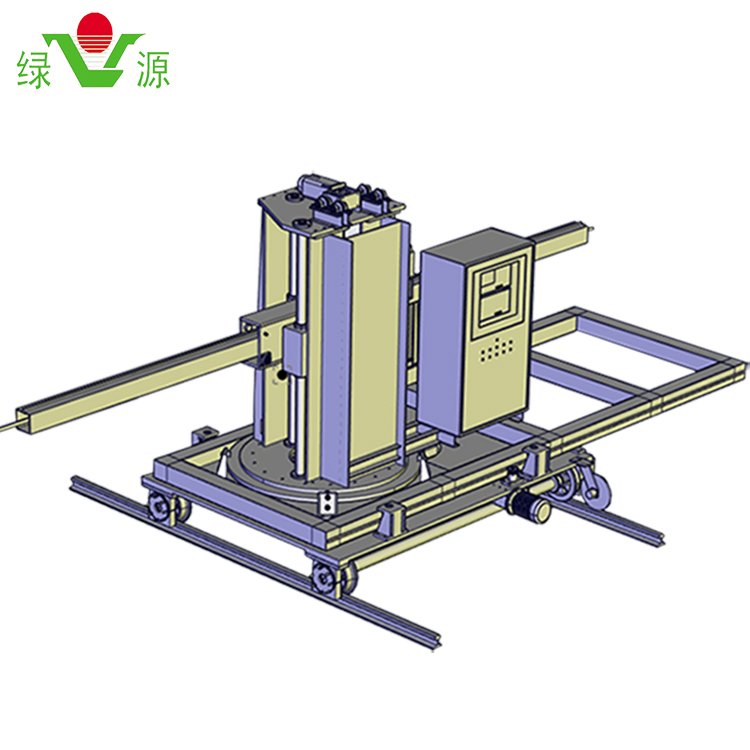

Automatic aluminum melting casting refining equipment

Automatic aluminum melting casting refining equipment

Technical scheme. In general, the refining and purification of molten aluminum in melting and casting plants involves manual operation of a 6-7-meter blowpipe extending into the molten aluminum to move back and forth, injecting the refining agent and nitrogen into the molten aluminum. Because of the high temperature in front of the furnace, manual operation Workers consume a lot of physical learning and use, and they may not be able to move the blowpipe uniformly, which affects the quality of the product. This machine moves according to a certain trajectory in front of the furnace, and sprays the refining agent evenly in the aluminum pool. The route and time can be set by programming to achieve the best effect. Due to the mechanized operation, it is not affected by human factors. Product quality is controllable.

The workers operating in front of the project innovation point are generally about 16,000 yuan a month, and because of the high temperature, long-term work will cause great damage to the human body. Generally, two to three people are required to cooperate each time, and each time it takes about 30 minutes. , This machine only needs one key to start, and it is far away from the heat source, and the work intensity is low.