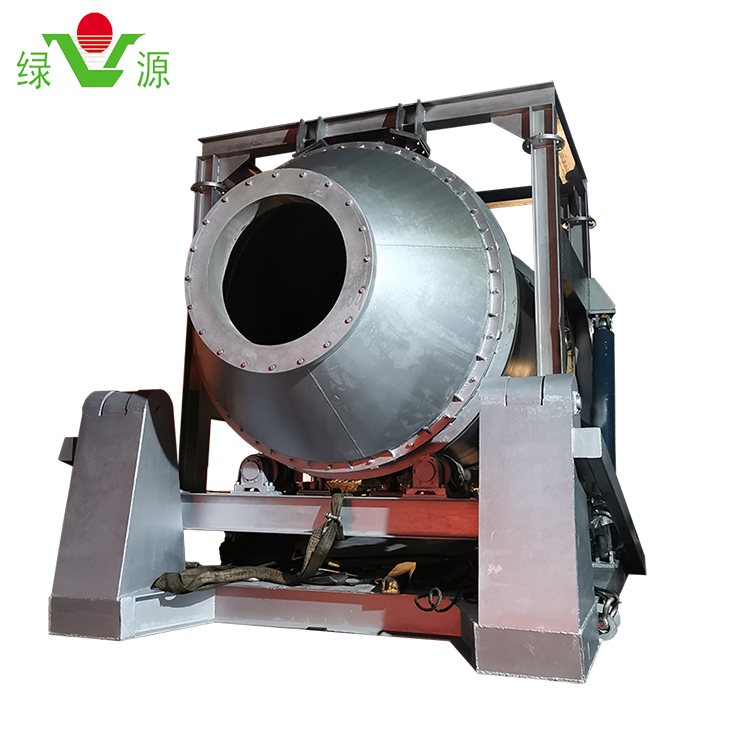

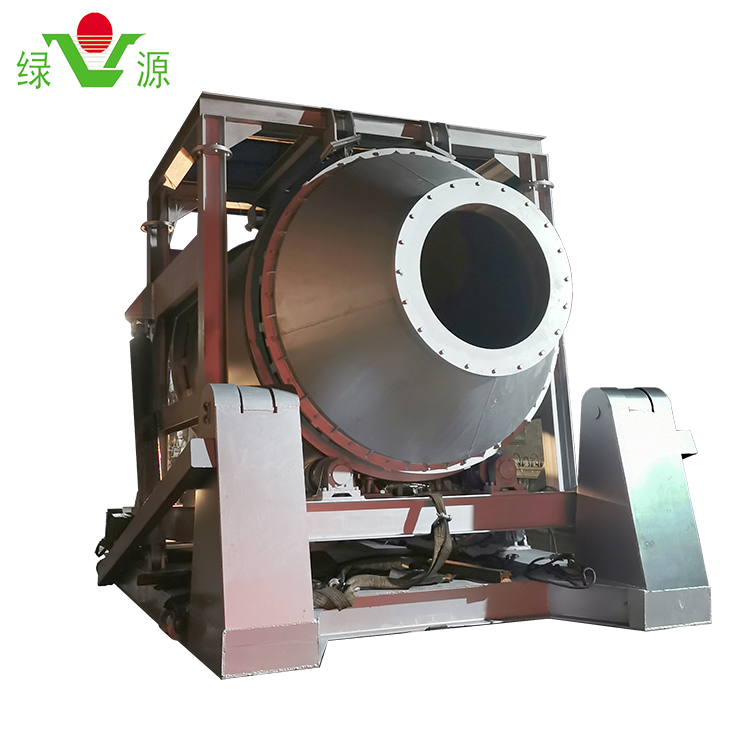

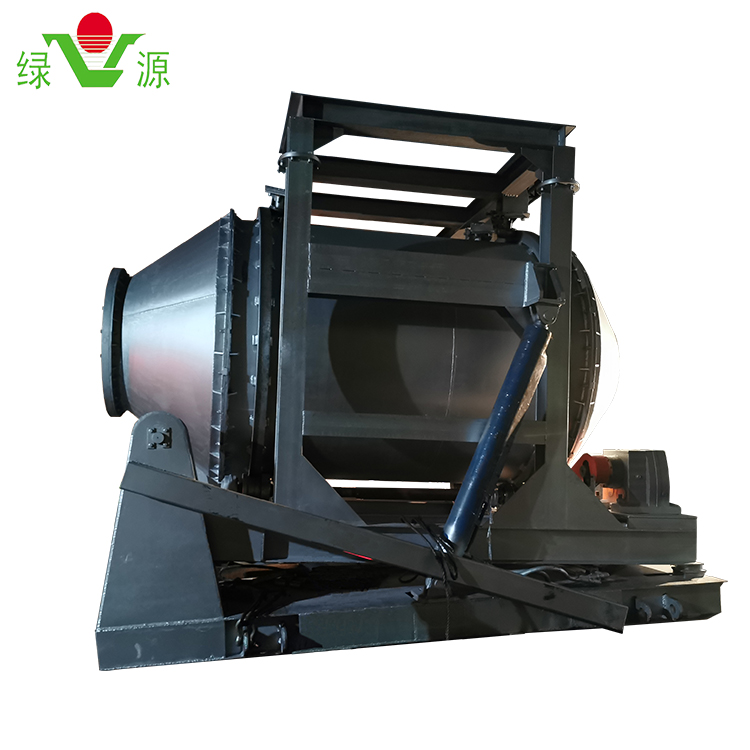

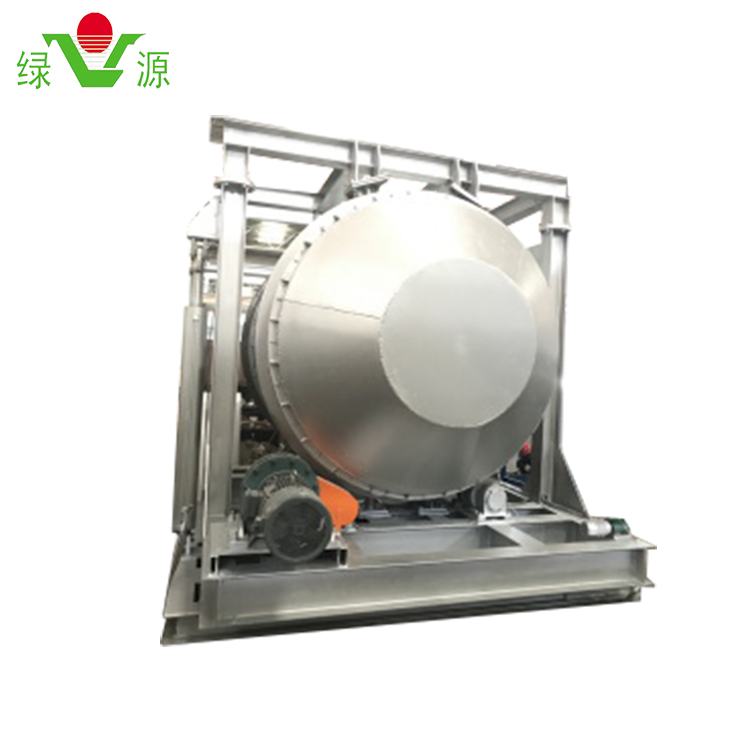

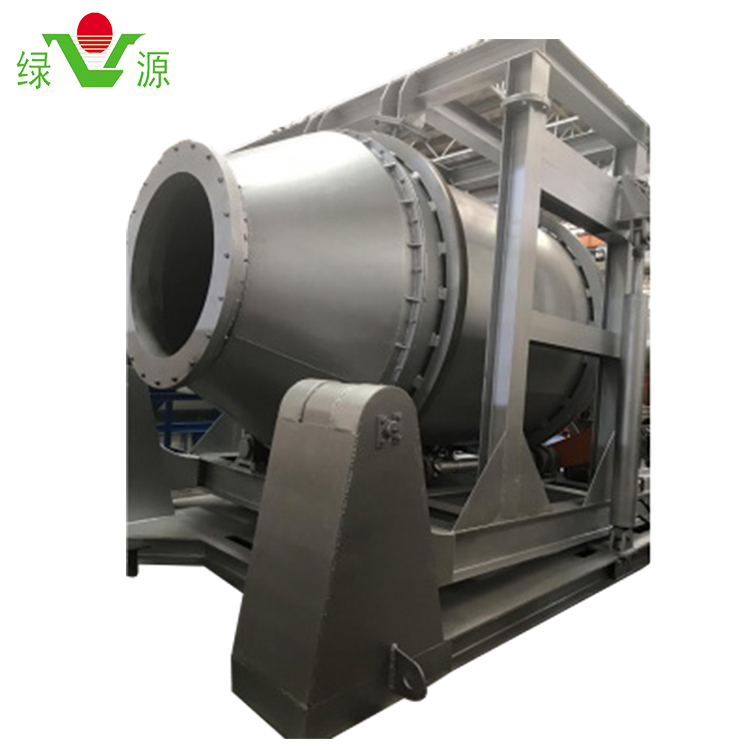

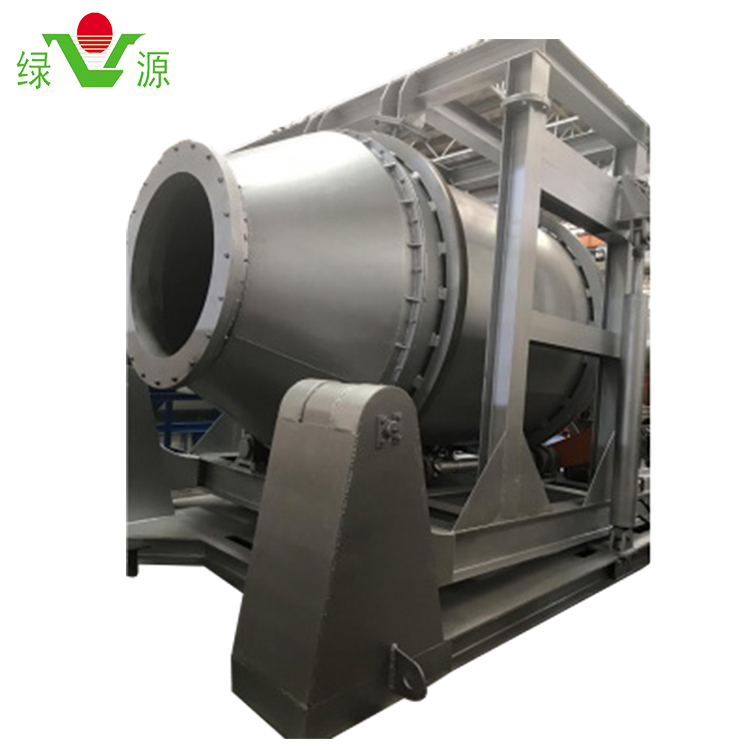

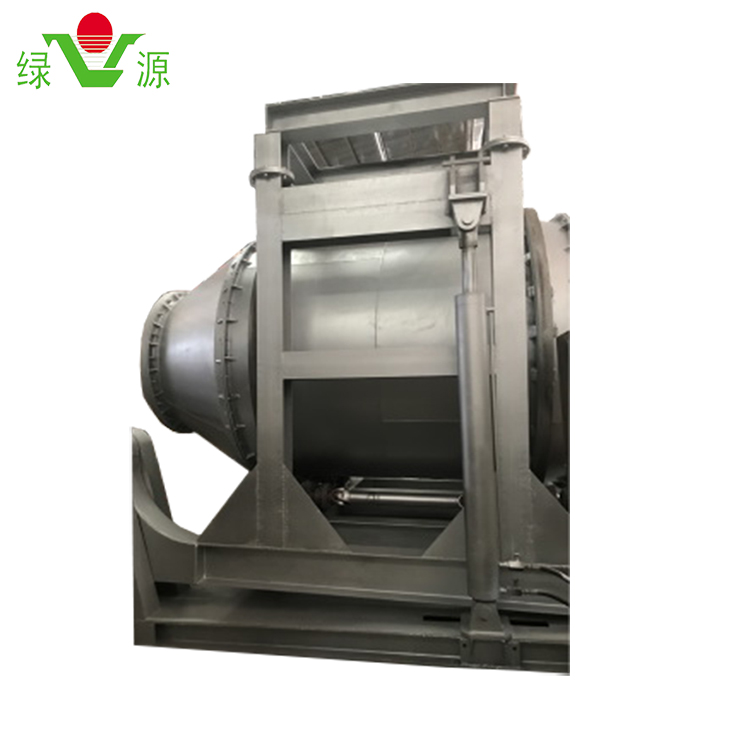

Tilting Rotary Furnace for Scrap Recycling for Lead and Foundry Casting Returns

Tilting Rotary Furnace for Scrap Recycling for Lead and Foundry Casting Returns

Rotary furnace

Main features: Rotary kiln is professionally used to treat hot slag from kiln grains. The rotary kiln rotates and stirs, and uses the spontaneous combustion of aluminum ash to cause high temperature

(occasionally adding a blender), thereby increasing the melting speed of aluminum and the temperature of aluminum water, and promoting The viscosity of the molten aluminum is reduced, the

molten aluminum and the aluminum ash are peeled off, and the molten aluminum in the aluminum slag is recovered after precipitation of the molten aluminum, which can reduce the aluminum

content in the aluminum slag to less than 15%. This product has stable performance, simple structure and mechanization. Low labor intensity in operation, strong processing capacity, high aluminum

recovery rate, concentrated dust and other advantages.

Aluminum slag ingot transfer cup Specification 300-800kg Open aluminum soup transfer bag Specification 500-1500kg Aluminum liquid transfer bag Specification 300-800kg